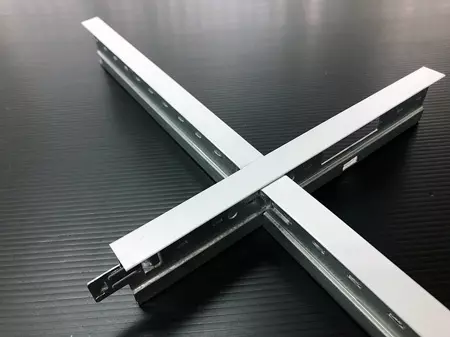

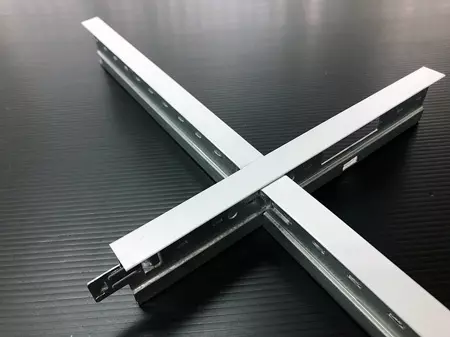

Fire rated - butt end

Introduction

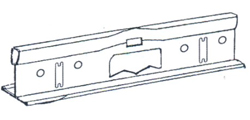

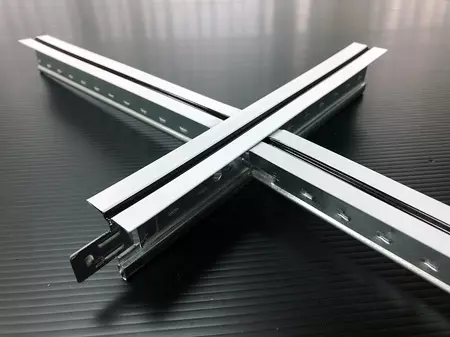

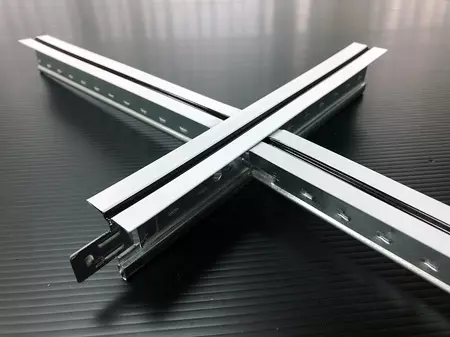

Our ceiling suspension grids are double web cold-rolled sections, manufactured from hot-dipped galvanized steel, conforms to JIS G3302 SGCC. The tees section is with pre-painted capped. It is given to ensure that the system is manufactured to a very high quality level.

The Main Runner is slotted for cross tees at 150mm or 6" centers to give maximum flexibility in the ceiling lay out.

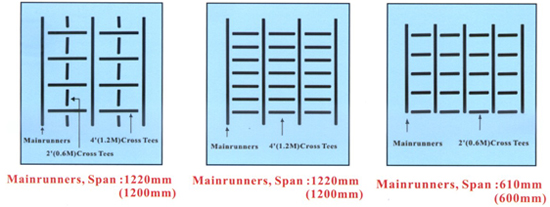

Types of combination

1200 x 600mm SIZES

DOUGLAS ceiling suspension grids comprises main runners installed at not more than 1200mm centers, securely fixed by pre-straightened suspension wire. The wire shall not more than 1500mm from the main runner splices, or expansion joints, and the maximum distance from the wire to the perimeter of the ceiling shall not exceed 450mm and otherwise at 1200mm centers.

Also, the main runners splices are to be staggered and not less than 450mm from the perimeter. Spanning between main tees are 1200mm cross tees at 600mm centers.

600 x 600mm SIZES

Same mentioned above, only add: 600mm cross tees spanning between 1200mm cross tees 600 module.

Specification

- Butt end, color : White

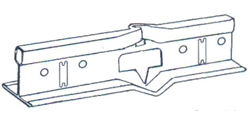

System consists of

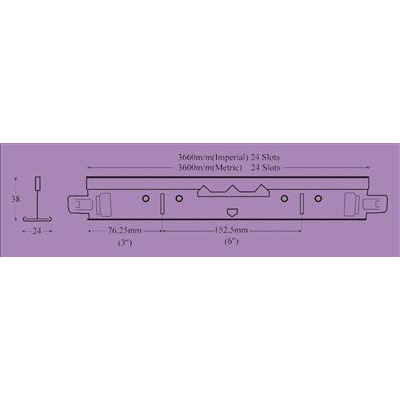

G.I. : 0.35mm / Main Runner: 38mm (height)

| Item | Size in metric | Size in imperial | G.I. thickness | Dimension |

| Main Runner | 3.6M (3600mm) | 12FT (3660mm) | 0.35mm | 24x38mm |

| Cross Tee | 1.2M (1200mm) | 4FT (1220mm) | 0.35mm | 24x38mm |

| Cross Tee | 0.6M (600mm) | 2FT (610mm) | 0.35mm | 24x38mm |

| Wall Angle | 3.6M (3600mm) | 0.40mm | 22x22 / 24x24mm | |

| Wall Angle | 3.0M (3000mm) | 0.40mm | 22x22 / 24x2 |

Advantages

- It is economical, easy to install, using less labor to complete the installation at minimum time as compared with conventional extruded aluminum tee system.

- Interchangeability of main and cross tees between systems, promotes lower inventory requirements and greater field flexibility.

- The straight entry locking feature of the section allows the system to be installed easily within close proximity of the overheads.

- The system promotes complete designs flexibility and it is capable of sustaining of loads normally designed into suspended tee system (refer to load table)

- Overlap type of cross tee provide complete flush joint, eliminating gaps between main runner and cross tees and ensure rigidity at fixtures.

- In line cross tees provide true double-lock action.

Fire expansion joint within each length of main runner.

Before Fire

Effect after exposure to fire conditions.

After Fire

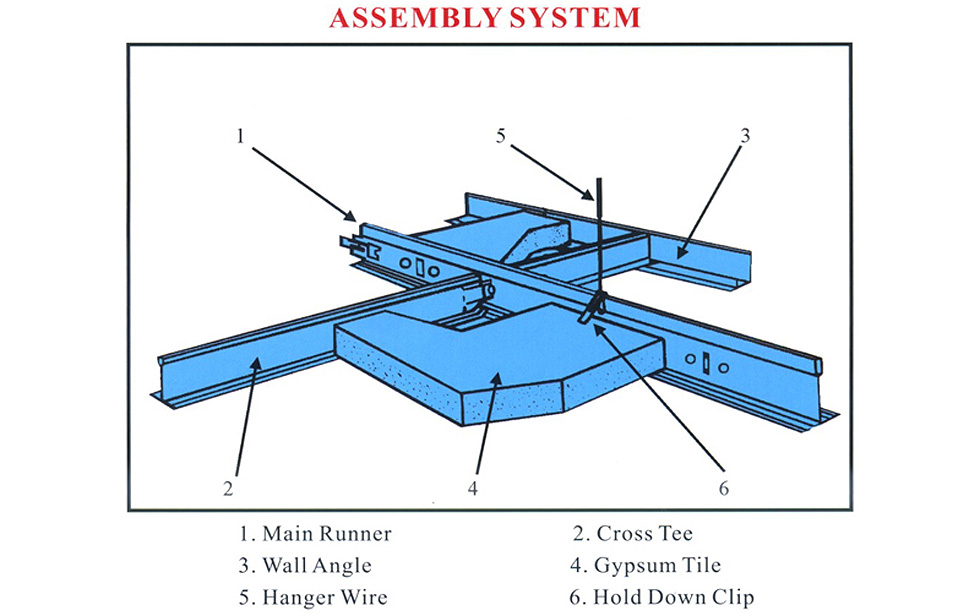

Installation Steps

- Step 1: Measuring and planning: Determine the lines for main runners and cross tees in such a way that tiles about the wall are at least half a tile (300mm)

- Step 2: Mark the desired ceiling height: Measure and mark the walls at all corners above the installation level. Snap a chalk line and test for level.

- Step 3: Inserting a nail between the wall and the wall angle at marked location serves as a good anchor for this purpose. Check to be sure the cross tee string is at 90°

- Step 4: Attach the main runners to the hangers

- Step 5: Install cross tees, assuring that they are adequately connected to main runners

- Step 6: Lay in panels, beginning at one corner and completing row by row.

Assembly

Each tee grids must be fitted always in the left position (Grey Color) of the slot. Hear the sound "Click"!

Disassembly

Need no tools!

Push, through the left thumb.

Then the tee's edge and simultaneously we pull the tee with our right palm.

Main Runners Disassembly

The disassembly must be done by a screwdriver with a slim tip.

- Files Download

Hot Products

Hot

Hot

Ceiling suspension grids/T-24 White

Hot

Hot

Ceiling suspension grids/T-24 White

Ceiling suspension grids/T-24 White is the most popular ceiling grid series moving in the market....

Read More Hot

Hot

Ceiling suspension grid/T-15 White

Hot

Hot

Ceiling suspension grid/T-15 White

Ceiling suspension grid/T-15 White is the slim type, which is with narrow width as 15mm only....

Read More Hot

Hot

Ceiling suspension grid/T-24 Black line

Hot

Hot

Ceiling suspension grid/T-24 Black line

Ceiling suspension grid/T-24 Black line is the product that we put one line in the center of T-24/White...

Read More Hot

Hot

Ceiling suspension grid/T-37 Screw up

Hot

Hot

Ceiling suspension grid/T-37 Screw up

Ceiling suspension grid/T-37 Screw up is galvanized steel made ceiling suspension grids with...

Read More