Cement fiber board

Introduction

The boards are made with high quality fiber and mineral substances as main raw materials, supported with advanced technological process and through high temperature, high pressure maintenance and special treatment.

Specification

- Mositure proof, excellent fire-proof performance, sound-proof, high strength, anti-sinking & stable dimensions

- Non-combustibility found

- Popular thickness: 6mm, 9mm & 12mm

- Available size: 1200x2400mm (metric) & 1220x2440mm (imperial)

Character

Moisture proof, excellent fire-proof performance, sound-proof, high strength, anti-sinking & stable dimensionsMain Use

- Internal and external wall parts

- Sound-adsorb wall parts

- Furred ceiling

Physical Property

- Density: 1.4g/cm3

- Moisture content: 10%

- Water absorption: 55%

- Thermal conductivity: average ≥ 0.20W/MK

- Bending strength: transverse ≥ 11N/mm2, vertical ≥ 8.5N/mm2

- Anti-freeze: no distortion after 25 repeated cycles of freezing and thawing

- Anti-flex cracking strength: 10 MPa

- Water-impermeability: through water immersing for 24HR, no water drop appearedon bottom surface.

Laboratory Test Pass

- Standard Test Method for Behavior of Materials in a Vertical Tube Furnace of 750°C: ASTME136:2011

- Test for Strontium Sulfide : Negative (undetectable)

Installation Steps on Wall Partition

Mark the building position with an inked string, according to blueprint. Secure the tracks on ceiling and floor by gunpowder nailing, and cut the studs into correct dimension, according to actual height. Insert the studs laterally into the tracks. Fix the boards on one side & fill in acoustic and thermal insulations. Seal boards on the other side, fill the joints. Painting or pasting wall papers.Board Fixed

Firstly cut the board into the dimensions what needed. Board is fixed on keel in anchoring seam way topping screw: the interval of tapping screw is generally about 200-250mm with screws sinking 0.5mm under the boards face. The expansion seam of about 4mm between board should be kept. The shrouding should be fixed from the middle to the four sides and cannot be operated at multi-point simultaneously to avoid generating inners stress to make board material bucking. Before board being fixed, depending the needs, glass cotton or rock cotton can.- Files Download

Hot Products

Hot

Hot

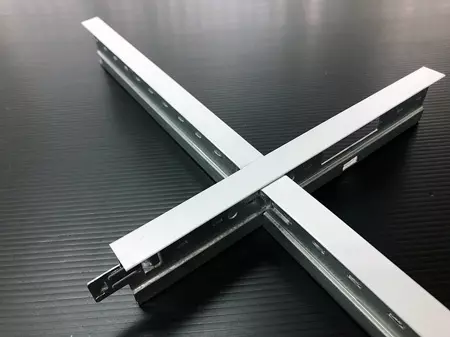

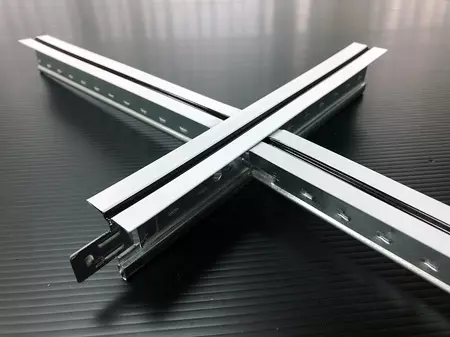

Ceiling suspension grids/T-24 White

Hot

Hot

Ceiling suspension grids/T-24 White

Ceiling suspension grids/T-24 White is the most popular ceiling grid series moving in the market....

Read More Hot

Hot

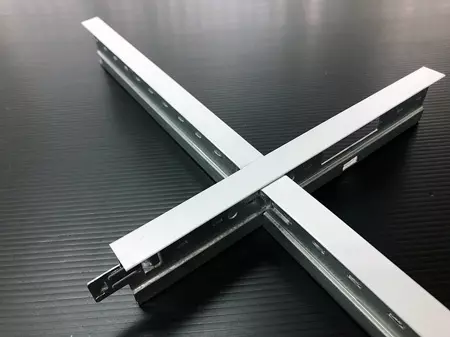

Ceiling suspension grid/T-15 White

Hot

Hot

Ceiling suspension grid/T-15 White

Ceiling suspension grid/T-15 White is the slim type, which is with narrow width as 15mm only....

Read More Hot

Hot

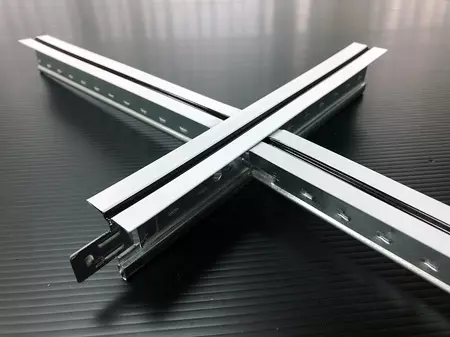

Ceiling suspension grid/T-24 Black line

Hot

Hot

Ceiling suspension grid/T-24 Black line

Ceiling suspension grid/T-24 Black line is the product that we put one line in the center of T-24/White...

Read More Hot

Hot

Ceiling suspension grid/T-37 Screw up

Hot

Hot

Ceiling suspension grid/T-37 Screw up

Ceiling suspension grid/T-37 Screw up is galvanized steel made ceiling suspension grids with...

Read More