Drywall partition system

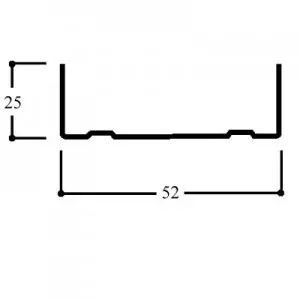

Pattern No: Track 52

Introduction

The system is made of durable galvanized steel, usually it uses gypsum boards as surface material. It is widely used in offices and residential building for its easiness of installation. Compared with wooden board, gypsum boards can provide a safer and fire-resistive wall. And, compared with bulky brick wall, it can greatly reduce the weight of building. Besides, thermal and acoustic insulation product may be filled in partition frame to create a safe and quiet environment.

The system is made of durable galvanized steel, usually it uses gypsum boards & calcium silicate board as surface materials.

The track may be fixed on the surface of ceiling and floor by gunpowder nailing.

Choose the track of different width according to the thickness of wall. Better not fix the gypsum boards on the tracks to prove a possible displacement preventing the crack and damage of wall while earthquake happens.

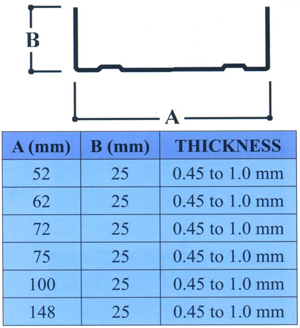

Specification

- Size: 25x52x25mm

- Available thickness: 0.45-1.00mm

- Available length: standard - 3.0M, but other lengths are available as per request

Applications

Factories, department stores, hospital, office buildings, residences, restaurants, etcFeature

- Dry wall partition system is widely used in offices and residential buildings for its easiness of installation. Dry wall partition system is made of durable galvanized steel. Usually it uses gypsum boards as surface material. Compared with wooden board, Gypsum boards can provide a safer and fire-resistive wall. Compared with bulky brick wall, it can greatly reduce the weight of building. Besides, thermal and acoustic insulation product may be filled in partition frame to create a safe and quiet environment.

Advantages

- 1. Excellent fire resistive ability. Suit residuals and public places.

- 2. Fast installation. Easy to control the construction progress.

- 3. Combinative construction. Easy to keep work places clean.

- 4. Good vibration absorbing ability. Suit buildings on seismic belt.

- 5. Fast reconstruction for easy assembling and dismantling.

- 6. Filling acoustic insulation can enhance the sound-proof ability.

- 7. Surface of the walls are smooth. Easy to paint or paste wallpaper.

- 8. Electric wires are hidden in the wall

- 9. It is easy to drill through the wall for construction.

- 10. It could be applied under the original ceiling

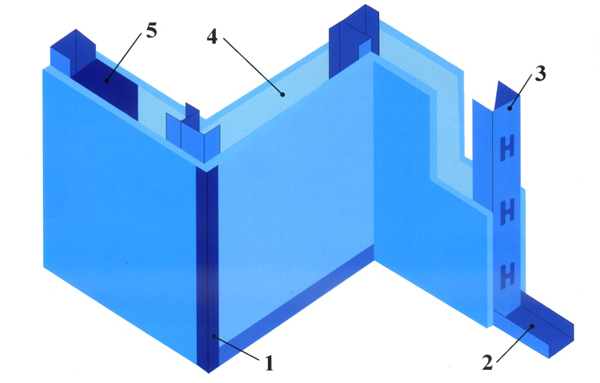

Dry Wall Partition System

1. Dry Wall Angle

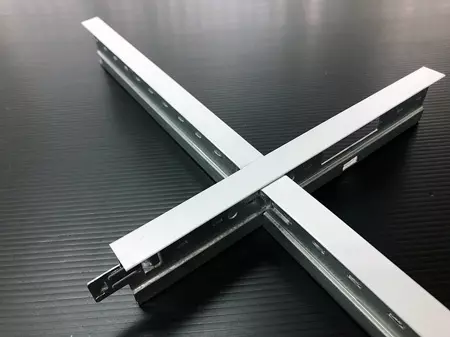

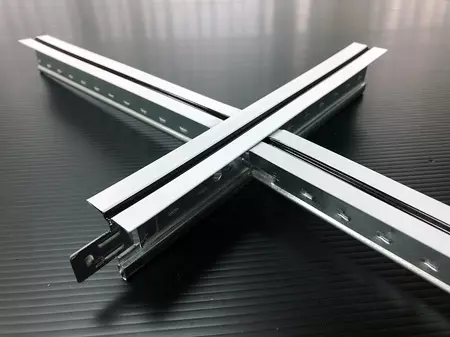

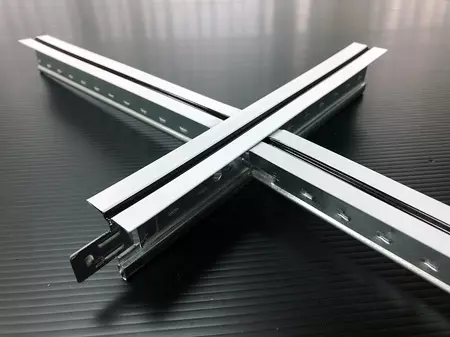

2. Track

3. Stud

4. Gypsum Board

5. Insulation

Installation Steps

Step 1: Mark the building pOosition with an inked string, according to blueprint.

Step 2: Secure the tracks on ceiling and floor by gunpowder nailing.

Step 3: Cut the studs into correct dimension, according to actual height. Insert the studs laterally into the tracks.

Step 4: Fix boards on one side.

Step 5: Fill in the acoustic and thermal insulations.

Step 6: Seal boards on the other side.

Step 7: Fill the joints. First, apply putty to joints. Then stick joint stripes and trowel them. After putty dry (about 24H), grind the exposed putty with abrasive paper. Repeat the same to separately apply the other two layers of putty with no joint stripes.

Step 8:Painting or pasting wallpapers.

- Files Download

Hot Products

Hot

Hot

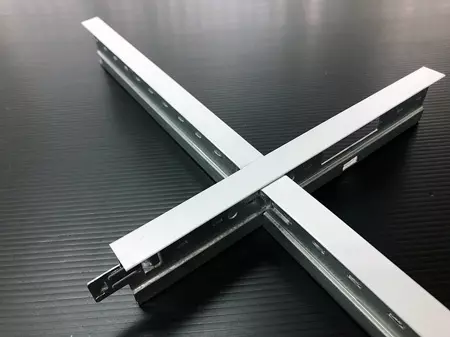

Ceiling suspension grids/T-24 White

Hot

Hot

Ceiling suspension grids/T-24 White

Ceiling suspension grids/T-24 White is the most popular ceiling grid series moving in the market....

Read More Hot

Hot

Ceiling suspension grid/T-15 White

Hot

Hot

Ceiling suspension grid/T-15 White

Ceiling suspension grid/T-15 White is the slim type, which is with narrow width as 15mm only....

Read More Hot

Hot

Ceiling suspension grid/T-24 Black line

Hot

Hot

Ceiling suspension grid/T-24 Black line

Ceiling suspension grid/T-24 Black line is the product that we put one line in the center of T-24/White...

Read More Hot

Hot

Ceiling suspension grid/T-37 Screw up

Hot

Hot

Ceiling suspension grid/T-37 Screw up

Ceiling suspension grid/T-37 Screw up is galvanized steel made ceiling suspension grids with...

Read More